First Class Dewatering System’s is an important part in the construction process that involves the removal of groundwater or surface water from a construction site to allow for safe and effective construction activities.

First Class Piling Dewatering System

Dewatering is typically required for excavation, foundation work, reliving lateral pressure off shoring walls and other construction activities that involve working below the groundwater table.

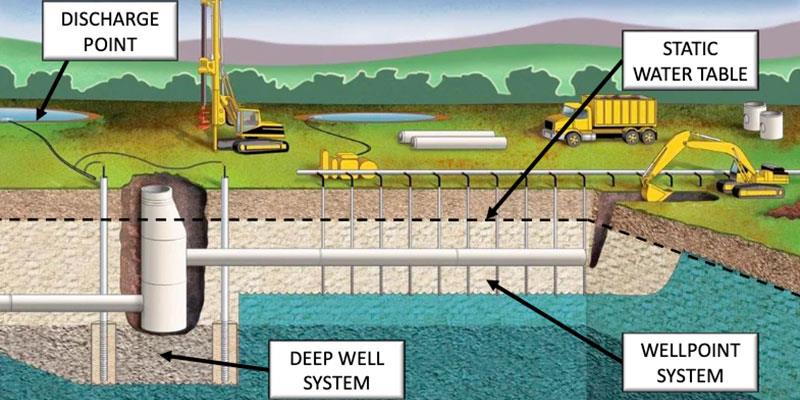

Dewatering use’s wellpoints, which are installed around the perimeter of the excavation area. Wellpoints are small-diameter pipes with screens or filters that allow water to flow into the pipe while preventing soil particles from entering. The wellpoints are then connected to a header pipe, which is connected to a pump that removes the water from the site.

The process of dewatering begins with the installation of wellpoints around the perimeter of the excavation area. The wellpoints are installed by drilling a small hole into the ground and inserting the wellpoint pipe into the hole. The pipe is then surrounded by a filter material, such as sand, gravel, or geotextile fabric, to prevent soil particles from entering the wellpoint.

Once the wellpoints are installed, a vacuum pump is connected to the header pipe to create a vacuum in the wellpoints. This causes water to flow into the wellpoints and through the header pipe to the pump, where it is removed from the site.

Dewatering is important for several reasons. First, it allows for safe and effective construction activities by reducing the risk of soil collapse, which can cause injuries or damage to equipment. Second, it allows for the installation of underground utilities, such as pipes and cables, which can be damaged by water if not properly dewatered. Finally, it helps to prevent damage to nearby structures and the environment by reducing the risk of settlement and erosion.